Description

Tempered glass is a type of glass that increases the strength of the glass by 6 to 8 times during a rapid heating and cooling process. This type of glass is modified in such a way that if it breaks, it will become very small and safe pieces. In fact, more precisely, tempering is a process that can be performed on any type of glass. In fact, it can be said that ordinary glasses are no different from this glass in terms of materials. Normal glass can be converted into tempered glass during the tempering process. The glass selected for the tempering process can be reflex colored glass, etc. As mentioned, the strength of this glass increases 6 to 8 times after the hardening process. Tempered glass is used to make office partitions as well as glass offices.

How to do the glass tempering process

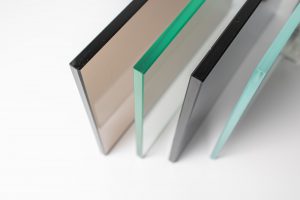

The first step in the process of making tempered glass is choosing the desired dimensions for the glass. The reason for this is that performing any actions such as cutting, drilling, etc. It will cause the glass to fall into danger. After cutting the glass, its four edges are polished with a diamond stone. After cutting the glass and putting a diamond stone on its edges, the glass is transferred to the furnace. In order to perform the tempering process of ordinary glass, it is necessary to heat it uniformly to the softening temperature, which is around 700 degrees Celsius. After heating the glass, the rapid cooling process should be done in the next step by blowing cold air pressure on both sides of the glass uniformly. During the rapid cooling process, the outer layers of the glass will definitely cool much faster than the inner layers. This causes compressive stresses to occur on the surface of the glass, and tensile stresses will also occur in the central part of the glass. These created tensions cause ordinary glass to become very strong and become tempered glass. It should be noted that if the process of cooling the glass is done slowly, it will create glasses with the ability to be semi-hardened. If the glass hardening process is done incompletely, the desired glass does not have the necessary resistance. This issue shows the difference in the quality of tempered glass available in the market in terms of quality. These surface tensions are 100 Mpa and tensile about 50 Mpa, which increases the probability of breaking the glass. The glasses that will be resistant with this method will be 4 to 5 times more resistant to the pressure of mechanical loads, wind, heat, different types of impacts compared to ordinary glasses that have the same thickness and dimensions. However, other characteristics of glass such as chemical composition, color, percentage of light transmission, melting point, physical characteristics and expansion coefficient will not change in any way. Tempered glass is produced in Sepenta factory in different sizes, designs, colors and thicknesses. The thickness of the glass produced in the Sepenta glass factory can vary from 4 mm to 19 mm according to the buyer’s needs. The higher the thickness of the glass, the greater its resistance and security.

Be careful that glasses with high thickness (19 mm) have special cases, and the thickness of building tempered glass for balconies, windows is produced in diameter of 4 mm to 8 mm.

Sepenta glass tempered glass is produced and supplied in customized sizes in the form of laminated and colored glass, double-glazed glass, suitable for spider glass facades, curtain wall facades.

Tempered glass

This product is one of the products that have brought about many changes in the glass industry and the glass production factories are continuously developing.

With years of experience in the field of manufacturing and production in different dimensions and designs, Sepenta Glass factory supplies all kinds of tempered glass at the best price. For information on the price and order in customized dimensions and special features suitable for the building facade project, contact the sales experts of Septa Glass at 02188102398.

Advantages of using tempered glass

Toughened glass has received a lot of attention during construction today. These glasses are popular because they are unbreakable. This product has many uses at home and in different businesses.

- High strength: Tempered glass is much stronger than ordinary glass. The process used in the production of this type of glass will create a strong bond between the molecules in the glass. This shows that this type of glass is very practical and suitable for cases that require high safety and strength. Items such as car and train windshields, windows, and its use for laboratories, as well as glass corridors, etc., are suitable.

- Safety: The main, most important and most valuable advantage of tempered glass is the safety created by these glasses. The use of these glasses will reduce the risk of injury by broken glass shards. Broken pieces of glass are a very serious danger that can lead to death. This type of glass is very popular due to its ability to break into very small and non-smashing pieces. Due to this feature, today there are many applications for tempered glass.

- Heat resistance: Tempered glass is more heat resistant than normal glass. This high resistance in tempered glass is one of the other effects caused by the glass tempering process. During the tempering process, due to the application of high heat to the glass, its molecules will become highly resistant to high temperatures. After this process is applied to the glass, it will not melt or weaken if the glass is exposed to a direct flame. This property has caused this type of glass to be used for laboratory purposes, fire engines and buildings that must have high fire resistance.

- Very high transparency: the glass tempering process, in addition to making the glass very hard, also has a significant effect on its transparency and clarity. This type of glass is crystalline and very transparent. The high transparency of these glasses has made it used for screen cases, glass doors and windows.

- Versatility: Tempered glass is one of the most suitable options for any place that needs glass. Items such as car windshields, phone screens and computer monitors, gas stoves and microwaves, etc. are among the applications of these glasses. This type of glass is used to make glass bathrooms or glass structures that are frameless, such as partitions, as well as commercial doors. The use of tempered glass in residential and commercial spaces creates a creative and stylish effect.

- It is not easily scratched: the process of tempering the glass, in addition to making the glass resistant to heat, will also make it resistant to scratches. This property has made tempered glass a very ideal option for use in kitchen appliances, glass doors, mobile screen protectors, passenger vehicles and windows. These surfaces will remain flawless for a long time.

- It is available in different designs and groups: Tempered glass is available in a wide range of different designs and patterns. This diversity has caused it to respond to all kinds of styles and tastes. These glasses are used in different designs such as flute tempered glass, reflex tempered glass with different colors and designs, and tempered tempered glass with different sizes and dimensions and colors. Matte, colored, engraved and patterned finishes can be used in many industries.

Advantages of sepenta tempered glass compared to raw glass

- Raw glass can withstand heat up to 60 degrees, which is 300 degrees (that is, 5 times more) for tempered glass. Miral glass is 7 times more resistant to impact and is not damaged by wind, hail, heavy snow, etc.

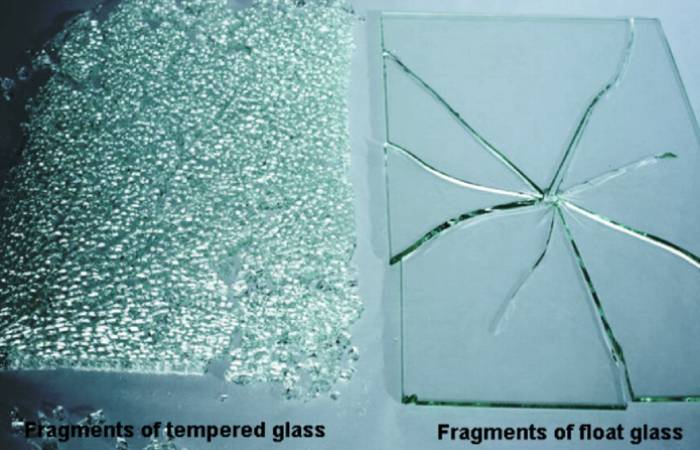

- Tempered glass turns into powder after breaking, but raw glass breaks into large pieces, which creates the risk of life and property damage.

- It is easier to move unbreakable tempered glass, because the raw glass will break if it is hit on any side, but the tempered glass will only break when the impact is seen from around it.

Selling tempered glass

Due to the strength and low resistance of raw glass against impact, cold and heat and the damage it caused in terms of money and life, a product called unbreakable glass was released in the world market. The first factory that produced this product was called Miral, and for several years unbreakable glasses were produced exclusively by this factory. Therefore, it is also known as Miral glass.

Types of tempered glass:

Tempered glass is one of the most widely used structures in the world. These structures are very popular due to their high resistance and stylish appearance. The types of this glass are crystal glass, flute glass, satin glass, laminate glass, Lacobel glass, and in this article we will explain the uses and features of each one.

Crystal tempered glass:

This type of tempered glass, as its name suggests, is crystal clear. Tempered glass is currently very popular among architects and interior designers. Crystalline tempered glass is most commonly used in the interior design of buildings. Due to the light passing through this type of glass, the space used in it will be bright. Among the uses of crystal tempered glass, we can mention cases such as shop windows, jewelry galleries, lobbies, banks, museums, commercial centers, and home interior decorations. Crystal hardness is produced from high-quality raw materials, which is why it does not have any impurities. The crystal shade will be made in white and blue colors. Its thickness varies from four to twenty one mil according to its application. Crystalline tempered glass is produced in two types: clear and super clear or extra clear. Clear glass is crystal clear and has green edges. Super Clear has a lot of transparency and the reason for this name is that this type of glass is more transparent than any other glass. Super Clear will be produced by several Iranian and European paints. Its difference with clear tempered glass is that the edges of the glass have blue or white color.

Flute glass:

Flute or smooth glasses are glasses that have a completely smooth surface without any waves or crookedness. This type of glass is very fragile on its own, but during the tempering process, its strength will increase five to six times compared to normal glass. This type of tempered glass is made with a thickness of 4 to 8 mm. The standard width of these glasses is up to 3 meters. Flute glass is used in making high quality mirrors and glass partitions. To recognize flute glass, you should pay attention to the color of the glass, and it is usually green.

Satin glass:

The fine materials in satin glass will make it opaque and will not create any waves or unevenness on the surface of the glass. These glasses become completely resistant during the hardening process. This type of glass easily passes the light and makes the space brighter.

Due to the fact that they are opaque, satin tempered glass is widely used to separate interior spaces from each other, such as partitions and bathroom glass. These glasses are available in different designs and colors, including mirrored, colored and colorless. They produce these glasses with a thickness of 4 to 12 cm.

Lacobel glass:

Lacobel glass is colored on the surface and colorless on the back. After tempering this glass, high resistance is created in it. Lakobel glasses have a wide variety of designs and colors. Lakobel glass is used both in interior decoration and in the facade of the building. The materials used to color Lacobel glass are completely harmless to the environment. The variety of colors of these glasses reaches more than 25 colors, which are very compatible with any interior design. This type of glass is 7 times more resistant to moisture and heat as well as ultraviolet rays compared to ordinary glass. The result of this high resistance is the prevention of decay and rust. Lakobel tempered glass installation is very easy. These glasses should reflect the received light, which will make the interior brighter. Gain itself saves energy. Anti-scratch is another advantage of Lakobel tempered glass, which allows you to print your desired design on it. Lakobel toughened glass has many uses in interior decoration due to its modern and stylish appearance as well as the variety of colors. There are things like mirror work, wall between cabinets, glass shelf table, glass partitions, dentistry, schools, etc.

Laminated glass:

Laminated glass is a great alternative to regular glass. These glasses have a very resistant structure that makes it impossible to break them. Laminated glass is increasing in popularity day by day due to its many applications. If you plan to install bulletproof glass for your home or workplace, these glasses are the most suitable option. In this article, we will introduce you to the features and benefits. Tempered glass is combined with several layers of plastic by combining two or more layers of tempered glass. They produce these glasses with different thicknesses, which will be processed by autoclave at a temperature of 1400 degrees using a pressure of 14 bar. The most common layer of this glass is polyvinyl butyral. Between these layers, transparent glass layers should be used to create features such as thermal insulation, solar insulation, increased protection against fire, etc. Laminated glass creates very strong layers while being transparent, which are a suitable option for the following applications.

Features of laminated glass

The main feature of this type of glass is that 99% will prevent the transmission of ultraviolet rays to the interior. These glasses have the ability to be made with more thickness with three layers of glass to create very resistant glasses to prevent theft. These glasses are actually bulletproof. The biggest reason why people want to install laminated glass is the high safety provided by these glasses. Glass that has multiple layers will not allow sound issues like normal glass. You will have a quieter home or workplace by using laminated glass. Because outside sounds cannot pass through this layer of glass. These glasses are very resistant to adverse weather conditions. Laminated glass has a long shelf life, which has a longer lifespan compared to ordinary glass. Laminated glass will have different prices according to its thickness and color. These glasses have a high installation price when they are used as glass facades for high-risk places such as tall buildings. Definitely, in these places, due to the difficulty of measuring the glass accurately, as well as the hard installation of the glass, you have to pay more. Glass ceiling is another application of laminated glass, which is very modern and stylish. The use of laminated glass for the interior walls of the building is very common today and has many fans. Using laminated glass to make glass pools is very creative, which creates a luxurious and modern food.

How to recognize laminated glass:

- As mentioned before, laminated glass is made of several layers of glass that have the ability to be tempered and PVB. The multi-layered nature of laminated glass gives it a greater thickness, which makes it easy to distinguish it from other glasses.

- The type of breaking of laminated glass has caused the distinction between this glass and normal glass. These glasses only stick to the middle layer when they are hit hard, if the glass is broken, it will not collapse.

- The shape and appearance of laminated glass: a series of laminated glass are designed in the shape of curves, squares, etc., which feature is unique to laminated glass.

Specifications of Miral glass

- The glass is more transparent

- It weighs less

- Costs are reduced

- It does less damage if broken

Comparison of unbreakable glass and raw glass

Everything you need to know about installing tempered glass

As we mentioned, tempered glass is one of the most widely used products that are used in many different businesses and industries. The method of tempering process is to bring the glass to the melting temperature and then cool it by applying cold air pressure. Through this process, the glass gets high resistance and high safety against high pressure and temperature. This type of glass is installed for all types of doors, windows, bathrooms, etc. You may also have a question about how to install tempered glass. We will teach you everything related to the installation of this glass in this article.

The difference between ordinary glass and tempered glass

- If we want to compare the installation of tempered glass with the installation of ordinary glass, we must mention a series of differences in both of these glasses. Compared to tempered glass, ordinary glass has little resistance, strength and thickness. This is if the tempered glass will become very resistant during the tempering process. These tempered glasses are very resistant to all kinds of impact and pressure.

- You can cut the dimensions you want to make regular glasses. These ordinary glasses have the ability to be cut during installation. This is if we have to cut the tempered glass before production so that no scratches are created during installation.

- Ordinary glasses are easy and very convenient to install, and special expertise is not required to install the glasses. However, installing tempered glass requires expertise and can be installed during a series of special steps.

Installation steps of tempered glass

- First of all, you should specify the type of application you intend for tempered glass. Determine its use for doors, windows, bathrooms, etc. This will help the expert guide you according to your needs.

- After the initial agreement and contract, you must send the exact dimensions of the desired space for which you intend to make glass to the factory. It is necessary to do this work by the manufacturer’s expert in order to make accurate measurements. The expert will be sent to the desired location for free and then he will get the exact size of the desired space.

- After sending the exact dimensions and size of the glass, it will be cut and produced. After cutting, the glass will be sent to the installation location using a special car and observing all safety measures. This will protect the glass from any damage. Finally, the installation expert should not go to the desired place to install and execute the glass. The whole process of installing this glass takes 34 working days from the time of receiving the order to the time of its delivery. It should be noted that if necessary, these steps can be installed within 24 hours.

As mentioned, installing tempered glass requires sufficient expertise and experience. It is necessary for the executive expert of tempered glass to have received the necessary training both theoretically and practically. In the training courses on the installation of tempered glass, they will be taught how to measure, place the accessories of this type of glass, as well as the possible risks that may occur during the installation process. We recommend that you use experts who have a lot of experience in this field to install your tempered glass.

Factors affecting the installation of tempered glass:

- Alignment: Tempered glass must be aligned from any angle. The alignment of the glasses is very important and it is necessary to do this work very carefully.

- Gluing of hinge washers: This is one of the very important things that should be considered when installing tempered glass.

The possibility of breaking the tempered glass during installation

As we mentioned, this type of tempered glass is highly resistant to any pressure and impact. Despite this high resistance, if the expert in question does not have enough experience in this field, it is possible to break the glass.

The cost of installing tempered glass

One of the most important questions that people will ask when buying tempered glass is how much it costs to install it. Most of these people will ask if they can install these things themselves. The answer to these questions should be no. Because the installation of tempered glass is completely specialized. The installation of these glasses requires a very accurate measurement with a special tool for this work. Otherwise, the possibility of damage and breakage of the glass is very high. There are various factors that affect the price of installing tempered glass.

How to install fixed tempered glass

Before we want to do the installation of fixed strength, its dimensions should be measured with the necessary accuracy. This should be done by a professional. After a precise measurement of the space, these desired dimensions will be sent to the factory for its implementation. In the next step, after preparing the glass and sending it to the desired place, the expert must first adjust the fittings for installation. Then the expert does the lay-down so that the tempered glass is placed correctly and with high precision in the desired location.

How to install rail tempered glass

Rail reinforcement will be installed in several steps as described below. After a precise measurement of the glass, he sends it to the desired location. The next step is to prepare the substrate for glass installation. If the dimension measurement is not done correctly, the expert will use a device called an inscription. In the next step, hangers and rollers will be installed. They install the floor guide or rail to move the glass. And in the last stage, they will install devices such as locks and handles on the glass.

Making unbreakable glass

To produce this product, after cutting, the raw glass enters the furnace so that the heat treatment increases its strength and resistance. Glass cutting cannot be done after heating the glass, also they use CNC machines to increase the speed of this work.

As we said, glasses are made in different dimensions. These dimensions can be about 120 mm and 300 mm and up to the largest size, which is common in the market, is 3200 mm by 8400 mm. Each of these dimensions has its own different efficiency and other dimensions are generally between these two sizes. Unbreakable glass can have a variety of geometric designs such as square, rectangle, rhombus, etc., which can be used in different parts of the structure. The specifications mentioned in the variety of dimensions and sizes include only a part of the variety of Miral glass.

Types of tempered glass

Since it has high resistance and security, it is gradually taking the place of ordinary glass and is used in the production of all kinds of glass. During the testing of tempered glass, many standards must be followed to guarantee its safety in every respect. In this section, we introduce three of the most widely used types: Normal: It is the first and most widely used type of this glass. The appearance is not much different from ordinary glass. This type of glass is produced in thicknesses of 4 mm to 19 mm. It is also used for industries, construction, decorative appliances, household appliances, kitchen appliances, etc. Double-glazed glass: This type of glass is very similar in appearance to double-glazed glass, but it has a much higher resistance. This product, like double-glazed glass, consists of two layers of glass of the same size and diameter, and the space between them is filled with compressed gas. This glass is generally used in construction and as window glass. Two layers: As we said, these glasses have high resistance and safety. Two layers have 7 to 12 times higher resistance against impact, heat and cold than ordinary glass. This type of glass is generally used in industries. Sekorit glass has other categories as well. Another category is in terms of quality and transparency, which includes the following types:

- Crystal

- Super Clear

- Clair

- flute

- sheet

Factors affecting the price of tempered glass

- Dimensions of tempered glass: the most important factors affecting the cost of installing tempered glass are their dimensions. The bigger the dimensions of these glasses, the higher their installation cost will definitely be. For example, the glasses that are installed for shops have larger dimensions compared to the glasses that are used for fences and windows. It is definitely natural that the cost of these glasses, which are used for shop doors, is higher.

- Type of tempered glass: As mentioned, there are two types of tempered glass: regular and laminated. Normal tempered glass, which has a thickness of 10 mils, is much lighter than laminated glass. The lower weight of the normal screeds has made them easier to install compared to the laminate screeds. Laminate flooring has a thickness of 20 mils. These glasses are made of several layers of glass with a plastic layer of glue. The multi-layeredness of laminated tempered glass makes them heavier compared to normal tempered glass. The cost of installing laminates is higher compared to the usual ones due to their high price and heavy weight.

- How to install tempered glass: Generally, tempered glass is installed in three ways: fixed, rail and hinged. In places such as the glass fence, the glass balcony, the glass facade of the building, they will install the security glass in a fixed way. But in places such as bathroom glass and shop doors, these tempered glass should be installed in the form of a rail. Therefore, it is obvious that due to spending more time and considering the dimensions of tempered glass that are installed in the form of rails, the installation cost is higher compared to its fixed type. It is necessary to install a frame for hinged glass doors. If the glass does not have a hinge, it should be ironed. In this case, in addition to the cost of installing this glass, the cost of iron is also added to the installation costs. The entrance doors of the glass rooms and the doors of the staircases of the buildings are of this type.

Buy tempered glass

Like any other type of glass, there are fake and original types available in the market. At the same time, you should start shopping based on your needs and goals. Our advice is to pay attention to the following points when buying.

- Absence of holes, embedding, lip filling, etc. on the glass

- The glass should not be filled with cardia and lips

- Absence of waves on the glass

- In horizontal flat furnaces, they are cured in the form of connections.

- Using adhesive cork (wide) when moving the glass, so as not to damage the glass

- The edges should have shiny flat diamonds

The price of tempered glass

As you can see, these glasses are determined in different thicknesses. The thicker your glass, the higher the price. Another important factor in determining the price of tempered glass is its strength, durability and quality. The brand of the glass manufacturer is also a very important factor.

To buy tempered glass in different colors and with special features, you can contact the specialists of Sepenta Glass through our contact page.

Reviews

There are no reviews yet.