Description

Bulletproof glass plays a crucial role in safeguarding vulnerable locations against armed attacks. It is commonly used in establishments such as jewelry stores, currency exchange offices, and specialized vehicles, providing an additional layer of protection against potential threats. While bulletproof glass may appear similar to ordinary glass, its manufacturing process incorporates specific principles and techniques to enhance its resistance.

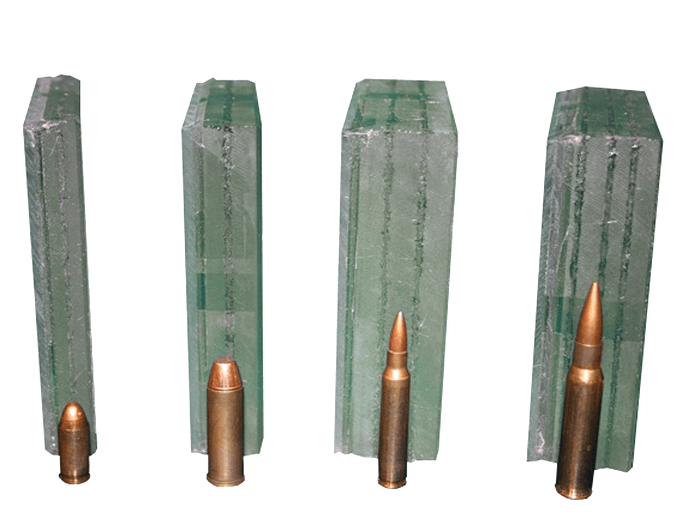

Types of thickness of unbreakable glass

Composition of Bulletproof Glass

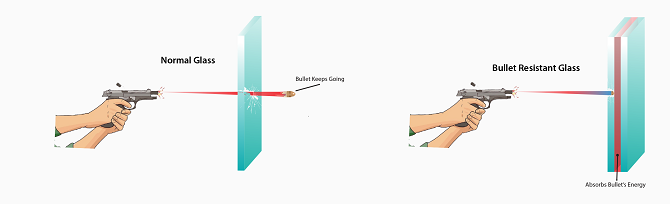

Bulletproof glass is typically constructed from three or four layers of glass bonded together using a polymeric interlayer, commonly made of polyvinyl butyral (PVB). The greater the thickness and number of glass layers, and consequently the number of PVB layers, the higher the resistance of the glass. When a bullet strikes the first layer, the plastic interlayer absorbs the impact and decelerates the bullet, preventing its penetration. These glasses remain intact even if they crack under severe force.

Bulletproof Glass Thickness

Bulletproof glass is available in various thicknesses to suit different applications. The thickness ranges from 20 millimeters to 78 millimeters. A 20-millimeter bulletproof glass can withstand a Colt handgun, while a 78-millimeter glass can resist even an assault rifle like the AK-47.

Cost of Bulletproof Glass

The price of bulletproof glass varies depending on its thickness and type. Generally, thicker glass is more expensive. It is essential to purchase from reputable suppliers to ensure the authenticity and quality of the bulletproof glass.

Applications of Bulletproof Glass

Bulletproof glass finds applications in various settings beyond jewelry stores and currency exchange offices. They are also used in buildings and laboratories where there is a risk of explosion and police offices. Other places where bulletproof glass is used include organizations with high security sensitivity, antique stores, banks, etc.

Types of Bulletproof Glass

The difference between original and fake bulletproof glass

As mentioned earlier, bulletproof glass is primarily made with PVB. However, a counterfeit version exists in the market, using EVA (ethylene-vinyl acetate) instead of PVB. This imitation type exhibits significant differences from the genuine bulletproof glass.

The manufacturing process of authentic bulletproof glass involves laminating multiple layers of polycarbonate and glass using PVB. Air is then removed from the layers, and the glass and plastic are bonded under high pressure, ensuring complete adhesion between the layers. When a bullet or a hard object strikes the glass, the first layer may perforate, but the plastic interlayer prevents further penetration, preventing the bullet from reaching the subsequent layers.

Features of Bulletproof Glass

-

Extended lifespan without discoloration

-

Transparent and colorless PVB interlayer

-

Customizable designs, dimensions, and curved or flat options

-

Excellent visibility and absence of distortions or waves on the surface

Bulletproof Glass for Jewelry Stores

Jewelry stores require exceptional security measures, including bulletproof glass, along with anti-theft doors and locks. Bulletproof glass for jewelry stores must not only resist impacts and scratches but also maintain high image quality. Therefore, it is crucial to use high-quality crystal for jewelry store glass to ensure clear visibility of the display. Additionally, due to the sensitivity and importance of jewelry stores, these glasses must withstand heavy impacts and bullets, necessitating a higher thickness.

History of Bulletproof Glass

This practical glass was invented in 1878 by French artist and scientist Édouard Bénédictus. Like many groundbreaking inventions, it arose from an accidental discovery when a glass bottle remained intact after falling to the ground. Bénédictus investigated this phenomenon and developed the first bulletproof glass, incorporating a celluloid layer between glass layers. The patent was registered in 1909. Various other plastics were also tested. However, the concept of using polyvinyl in laminated glass was introduced in 1936 by Earl Fix of Pittsburgh Plate Glass. This material proved to offer superior safety features and gained widespread adoption.

Reviews

There are no reviews yet.