Description

Glass is one of the most widely used materials in building construction, both for interior and exterior applications. In the past, only single-pane glass was available. However, in recent years, a wide range of glass types has been developed, including laminated double-glazed glass, tempered glass, bulletproof glass, and more, each with its own unique purposes and capabilities.

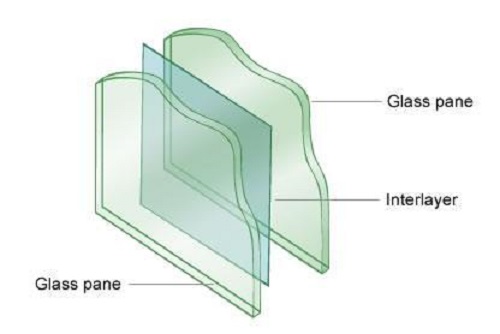

Production of Laminated Double-Glazed Glass

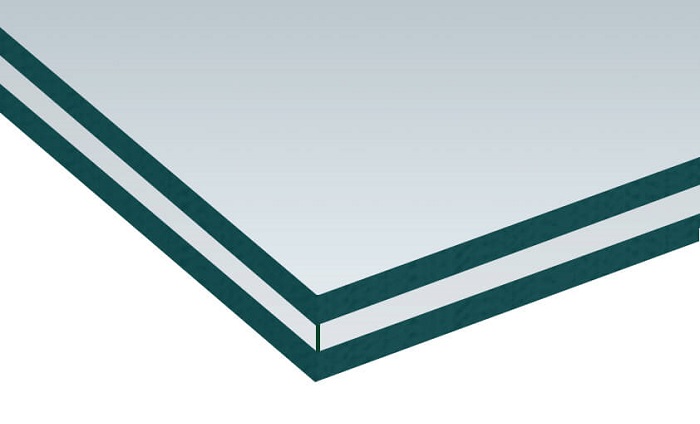

Laminated double-glazed glass is highly durable and secure due to its multi-layered construction. The primary factor contributing to its exceptional strength is the PVB (polyvinyl butyral) film incorporated into its structure. Laminated glass is produced through a process involving multiple layers of glass and a PVB film at a specific temperature and pressure. The number of layers and the thickness of the PVB film used in this glass can vary depending on customer requirements and preferences. Currently, the most commonly used PVB films in the market have thicknesses of 0.38 mm, 0.76 mm, and 1.36 mm. Unlike ordinary glass, which shatters into sharp and dangerous pieces upon breakage, laminated glass remains intact and non-hazardous when broken.

The PVB layer creates a strong bond between the layers, ensuring that the glass remains intact and prevents the individual glass pieces from shattering during impact.

Applications of Laminated Double-Glazed Glass in Buildings

Double-glazed glass is one of the most versatile types of glass used in various industries, particularly in the construction sector. Its unique properties make it an exceptionally practical choice. This glass offers a significant level of sound insulation, effectively reducing sound transmission. Additionally, it provides a degree of thermal insulation, contributing to energy savings.

Laminated glass, due to its strength and shatterproof nature, finds extensive applications in commercial and residential buildings, enhancing security levels. The most common uses of laminated double-glazed glass include elevators, glass stair railings, interior décor, and elevators. It is also used for glass floors, glass ceilings, skylights, glass facades, and other applications. This glass, due to its excellent sound insulation properties, is also employed as soundproofing material in environments such as hotels, airports, terminals, music recording studios, and similar settings.

Advantages of Laminated Double-Glazed Glass

Laminate is a recent addition to double-glazed glass. Not all double-glazed glass is laminated; only some have this feature. Now, let’s discuss the differences between laminated and ordinary double-glazed glass. Laminated double-glazed glass is a very strong and suitable sound insulator, meaning it does not allow any external sound pollution to enter the building. Laminated double-glazed glass is also an excellent heat insulator. In the hot season, it prevents the scorching heat outside the building from entering, and in winter, it prevents the exchange of cold and heat. This feature helps reduce energy consumption, which directly reduces energy costs.

Types of Laminated Double-Glazed Glass

Double-glazed glass is classified into different types based on its manufacturing process, customer needs, and preferences. The most prominent of these types include:

- Laminated tempered glass

- Lacquered laminated glass

- Laminated glass with stainless steel frames

- Colored laminated glass

- Printed laminated glass

Each of these glasses is designed and manufactured for specific purposes. Therefore, before purchasing, customers should gather sufficient information about the applications of these glasses and their specific needs. These glasses also have other models that are used for specific purposes.

“For consultation and purchase of various types of glass, you can contact Sepanta Glass, a glass manufacturing company with a long and distinguished history in this field.”

The price of laminated glass depends on the number of layers

Price of Laminated Double-Glazed Glass

Laminated double-glazed glass uses PVB film, which comes in various types. The quality and thickness of this film are crucial factors in determining the price of laminated double-glazed glass. Additionally, the quality of the glass used in the manufacturing process and the final color of the glass are other significant factors. The number of layers in laminated double-glazed glass is another important factor. Obviously, the more layers used, the higher the final price of the glass. While the price of these glasses is higher than that of ordinary single-pane glass, the advantages they offer outweigh the costs and significantly reduce energy waste expenses.

Factors to Consider When Purchasing Laminated Double-Glazed Glass:

-

Reputable Supplier: Choose a reputable and experienced supplier to ensure high-quality products and professional installation services.

-

Glass Dimensions: Accurately measure the dimensions of the required glass panels to ensure a proper fit and optimal performance.

-

Glass Type: Select the appropriate type of laminated glass based on your specific needs and preferences. Options include clear glass, tinted glass, and printed glass.

-

Frame Material: Choose high-quality frame materials that complement the aesthetics of your building and provide long-lasting durability.

-

Installation Expertise: Ensure the installation is carried out by experienced technicians to guarantee proper sealing, alignment, and overall performance.

Production Process of Laminated Double-Glazed Glass:

Glass Cleaning: The glass panels are meticulously cleaned to remove any impurities that could affect the bonding process.

PVB Film Application: The PVB film is cut to the desired size and carefully applied between the glass panels.

Pressing and Heating: The laminated glass assembly is subjected to high pressure and heat to create a strong and permanent bond between the glass layers and the PVB film.

Autoclave Treatment: The laminated glass is placed in an autoclave for further heating and pressure treatment, ensuring optimal adhesion and durability.

Quality Control: The finished laminated glass undergoes rigorous quality inspections to ensure it meets the highest standards.

Ordering Laminated Double-Glazed Glass:

Contact a Reputable Supplier: Consult with a reputable supplier who can provide expert guidance and assist you in selecting the most suitable laminated double-glazed glass for your project.

Provide Project Details: Clearly communicate your project requirements, including the dimensions, glass type, frame material, and any specific preferences or concerns.

Obtain Quotations: Request quotations from multiple suppliers to compare pricing and ensure you are getting the best value for your investment.

Review Specifications: Carefully review the specifications provided by the supplier to ensure they align with your requirements and expectations.

Schedule Installation: Once you have selected a supplier, schedule the installation date and ensure the installation team has access to the site and necessary equipment.

Conclusion:

Laminated double-glazed glass offers a compelling combination of sound insulation, security, energy efficiency, and aesthetic appeal, making it an excellent choice for a wide range of applications. By carefully considering the factors mentioned above and following the recommended ordering and installation procedures, you can ensure that your investment in laminated double-glazed glass delivers the desired benefits and enhances the value of your property.

Reviews

There are no reviews yet.